This machine adopts a programmable motion controller system, a valve island module, a remote module, and a bus layout, which enable intelligent operation and parameterization function settings.

This achieves sensitive machine control, stable operations, and smoother actions. The six station rotating mechanism enables the exchange of stations and non-stop execution of automatic cover paper feeding, gluing, positioning, guiding, edge covering folding, edge sealing, bottom sealing, inner folding, and pressing, all completed in one cycle. This enables paper transfer in a fully glued state, simplifying the box-making process and reducing space occupied. The six-station rotating mechanism permits uninterrupted exchange of workstations, and the box shaping mold adopts an integral expansion design to protect it from deformation under pressure. Detaching from the mold, the box is more flexible, achieving significant improvements in production efficiency. This versatile machine is widely used in producing high-end wine boxes, electronic product packaging boxes, cosmetic boxes, jewelry boxes, drawer boxes, and more.

Note

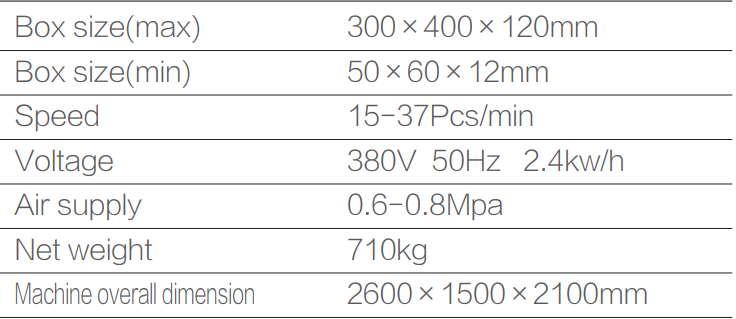

Pressing parts with single or double station can be optionally matched.

The cover paper gluing system can be optional according to white glue or hot melt glue.

The cardboard anti-counterfeiting buckle conveyor line and the bottle cap liner conveyor line are optional .

The size of the box is restricted by the size of the cover paper.

The company does not provide air compressors.

Several factors that affect the speed of the machine: raw materials, glue and operator proficiency.

Due to continuous innovation in product design, the above data is for reference only. and are subject to change without notice.

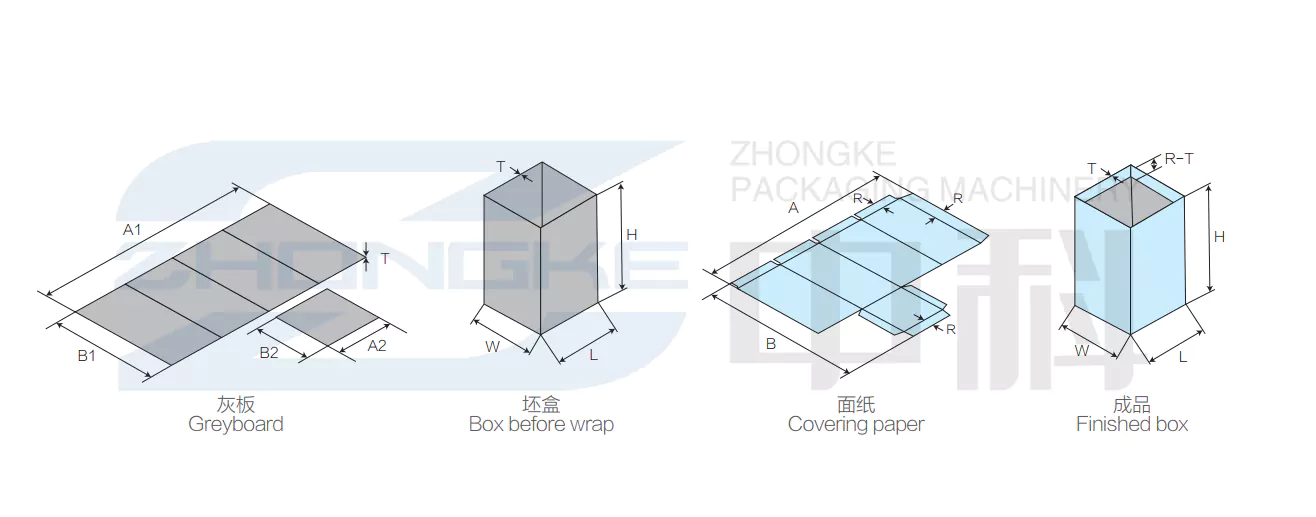

Box Craft Drawing